Chilling the Industry

Technology’s Stories vol. 8, no. 3 – DOI: https://doi.org/10.15763/jou.ts.2021.01.05.02

Following World War II, snow was so valuable to Vermont tourism that a writer for Vermont Life called it “white gold.”[1] With snow, the author reasoned, people could ski. And when people skied, Vermonters profited. Today states throughout the country embrace this rationale. On October 12 of this year, after the first snow, Loveland, Copper, and Arapahoe Basin in Colorado all fired up their snow guns despite the summer-long drought and the five forest fires still burning in the state. Snowmaking uses a lot of water, but the money from winter tourism stopped the county, the Forest Service, and the state from preventing these resorts from pulling water from precariously low streamflows. Snow, it turns out, is quite valuable. But only when it is in the right place, in the right amount, and at the right time. The problem for the ski industry, and their compatriots in government, is the inherent instability of snow and the frustrating unpredictability of snowfall.

In 1946 when A.C. Coleman wrote that article in Vermont Life, there were only 90 ski areas in North America.[2] Investment in infrastructure was small, and in some winters, Vermont lacked sufficient snow for a ski season. The weather in New England was too unreliable. Today there are over 470 ski resorts in the United States.[3] And the weather is less reliable today than in 1946. In 1951, The Pittsburgh Times reported on the new snowmaking machines, writing that “ski centers have called on science to supply them with snow when the weatherman fails.” The idea that snow guns stood in opposition to weather was common at the time and is mirrored today in articles such as “Ski Resorts Fight Climate Change With Snow Guns and Busses,” published by Wired only a few years ago.[4] The feeling is understandable. Rhetoric that puts technology in opposition to environment, like that in Wired, is quite common. But, as humanists and social scientists studying what they call “envirotech” have now argued for decades, few if any technologies stand outside the realm of nature. For snowmaking technology, it is acutely dependent on the two variables that these articles, written sixty-seven years apart, suggest the machines overcame – weather and climate. More specifically, snowmaking is dependent on the cold.

Figure 1 Vermont Life combined articles with lavish pictures. Source: archive.org

Snow has a vibrancy that sits at the center of the ski universe. It constantly changes, hour to hour, day to day, month to month, and year to year. It can also, like anything else, be changed by outside forces. A momentary burst of warm weather or winter rain can rapidly melt away natural snow, ruining a ski slope until the next snowfall. In places like the mountains of New England and upstate New York, where the Alpine ski industry was born, and which are famously cold and snowy, snowfall varies significantly each year. Weather in this region is uniquely complex. Pressure systems in the north Atlantic, snowfall over the Canadian plains, and warm air moving up the coast all determine whether places like Vermont will receive 50 inches or 160 inches over the course of the year.[5] Snow’s constant fluctuations at times benefit skiers. Snow can dry out, making it light and fluffy under the ski, or the hard crusty ice that forms on day-old snow can melt into soft and durable corn snow. But, this vibrancy can also devastate a ski day or a ski season. All it takes is too much sun or a brief rain shower.

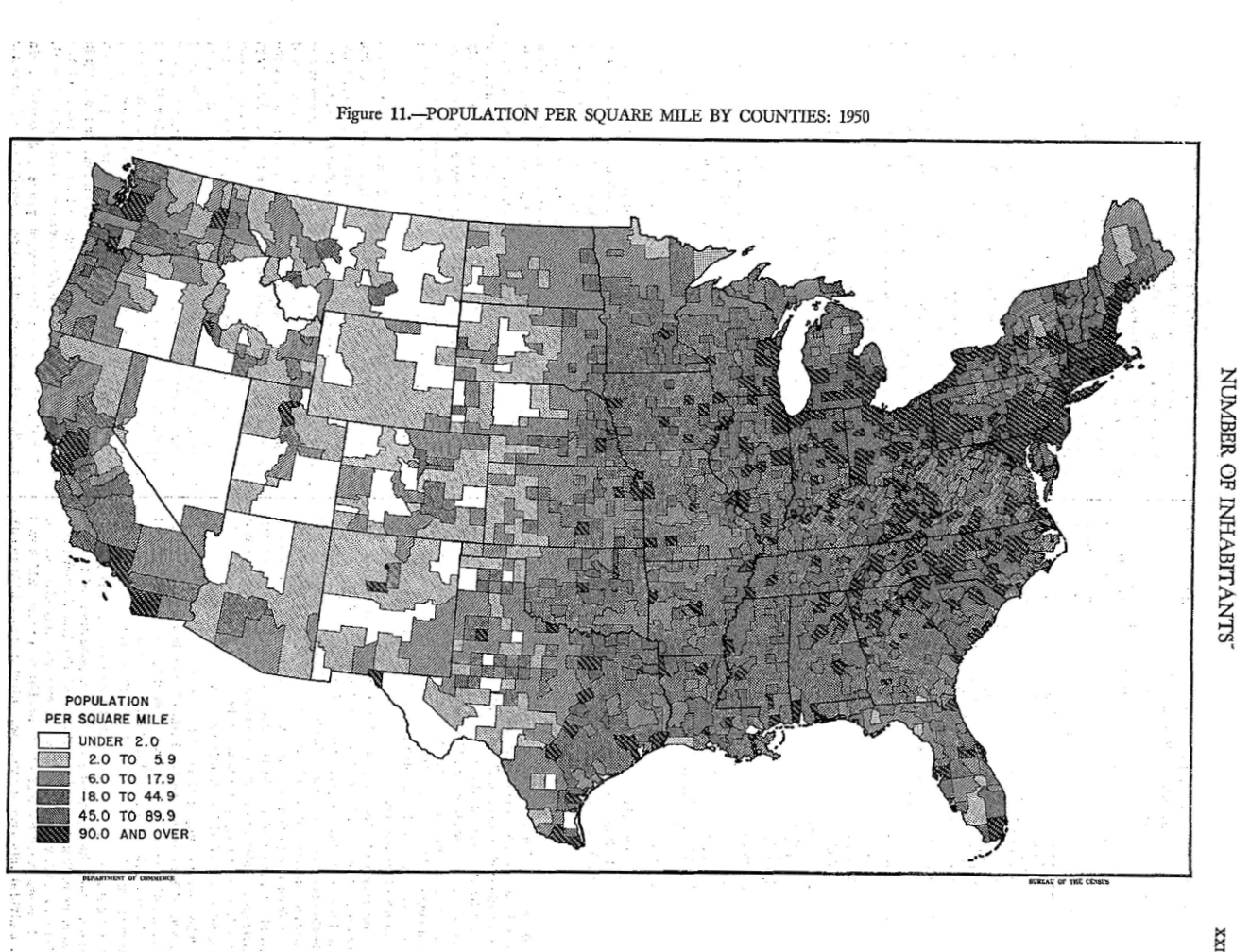

It was in the cold New England and the more moderate mid-Atlantic winters where the ski industry was born. Today the Appalachian Mountains boast 177 ski resorts. The snowmaking-dependent hills of the Midwest come second with 141, and the Sierras and Rockies combine for 152 (many of which are increasingly dependent on snowmaking). Despite the romantic appeal of Western skiing, the East is still a major hub of Alpine skiing. So, if snowfall was (and still is) so inconsistent in the East, and if the weather patterns were (and are, increasingly) unstable, one has to wonder how Coleman’s “white gold” was consistent enough to start an industry?

The first snowmaker was invented in 1950, but it was not the first attempt to modify snowpack. For instance, in 1934, the Toronto Ski Club faced a dilemma. They had planned a jumping competition, but the winter skies failed to cooperate. Instead of canceling, the Board of Strategy asked the University of Toronto for help. The club made arrangements to shave ice from the University skating rink in order to mimic snow. Fred Hall, who reported on the competition in the Canadien Ski Journal, described the shavings as “an excellent substitute.” The ice cost the ski club $80 (or $1 a ton), but he was adamant that the cost was worth it. Not only did the snow replacement successfully cover “the entire hill from tower to outrun, with about six or eight inches on the landing slope,” the “jumps made on that day were comparatively longer.”[6] Furthermore, $80 was an affordable cost for a ski jump. In the 1930s, ski jumping was the most popular type of ski competition in the United States. But with the help of Hannes Schneider, the films of Otto Lang, and the motivated organizing of Alpine ski clubs by conservationists like Irving Langmuir, Alpine skiing increasingly won the hearts of America’s elite winter tourists.

Downhill skiing’s first growth spurt was not the result of snow-mimicking or snowmaking. Instead, it was due to an innovation that changed how people moved uphill. In 1934, the first rope tow in America was built in Woodstock, Vermont, a town that was about thirty miles east of Rutland, and a way-stop on the soon to be complete Appalachian Trail. Although it is now one of many Vermont resort towns that boast quaint hotels and bed and breakfasts, at the time Woodstock was an epicenter of both summer and winter tourism. With the addition of a rope tow, the town quickly became one of the most popular year-round resorts in the country.

Rope tows dramatically changed the experience of skiing. Freed from trekking uphill, skiers saved time and energy. Previously a day of skiing began by strapping skins (usually from seals) to the bottom of their skis and slowly hiking up the mountain.[7] Tired, sweaty, wet, and with frozen feet, the skiers might have stopped for a snack or a brief lunch break. The length of the climb depended on the size of the mountain, but only after difficult work could the skiers begin their descent down the slope. By the end of the day, they were exhausted and had only briefly experienced the liberating sensation of the wind in their faces as their skis slid rapidly downhill.

Figure 2 A group of skiers who likely skinned up the mountain. Source: Wikimedia.

But the rope tow changed all that. It was a simple machine. And it was a cheap machine. In general, almost anyone could finance a rope tow, and farmers, hotel owners, and anyone owning a snow-covered hill began stringing them up. True to its name, it was a rope, often attached to an old car engine. The engine turned the wheel, and the rope moved upwards. Skiers then grabbed on, and the tow pulled them up the slope. In reality, building the machine was simpler than riding it. Riding a rope tow was a skill all to itself. Nevertheless, once learned, people could ski several runs a day, rather than just once.

Along with changing the nature of Alpine skiing, the rope tow changed the economics of ski centers. Once built, rope tow owners would charge people (usually around $1 per ride) to use the tow. This change was the first step towards modern ski resorts. Owners began expanding their ski hills, creating multiple slopes and investing in multiple rope tows, offering beginner, intermediate, and expert slopes. Skiing boomed. But these investments also came at a cost. The more money owners put into ski hills, the more they relied on consistent snowfall. And in the Catskills, western Massachusetts, Connecticut, and the Poconos, where city dwellers were flocking to take up this new sport, snow was often scarce. If ski centers and the hotels and boarding homes that housed skiers were going to maintain a winter tourist economy, they needed to guarantee the white gold which Coleman alluded to in Vermont Life.

The first chairlift in the United States was built in Sun Valley, Idaho in 1936 – the same year as Woodstock’s rope town. However, the chairlift took longer to take hold in the crowded East. While others in the west, such as Alta in Utah in 1939, also built a chairlift, the investment was riskier in the sometimes snow-starved Appalachian Mountains. But the East was also the most densely populated part of the country, so it was where most American skiers lived. The first chairlift in the east was built at Mount Mansfield, in 1940, by a diverse group of investors. The need for a corporation is an essential and often overlooked facet in the history of skiing because it demonstrated the new economic risk taken by people who hoped to build ski areas. While the rope tow created an increased need for reliable snow, chairlifts made it a necessity. Investors unsurprisingly wanted to see gains from their investments – their goal was to make money. But without guaranteed snow, chairlifts were a bad investment. And few places in the East originally invested in them. That said, although chairlifts were by and large a bad investment, they made rope tow ski hills look and feel tiny. People began to see the benefits of a larger ski center. It was precisely this desire to ski, and the potential to profit from it, that drove attempts to modify snowpack.

Figure 3 A U.S. Census Bureau map showing population density in 1950. Source: census.gov.

In 1947, one year after Coleman’s article appeared, a ski entrepreneur opened the multiple rope tow Mohawk Mountain to great success. But he found himself in financial trouble in December of 1949 when almost no snow fell in Connecticut. Over Christmas, Mohawk Mountain was brown. If white slopes meant you had struck gold, brown slopes meant you struck out. Panicked that his ski center would go under, Walter Schoenknecht – nicknamed “the Phenomenal Snow Man” by Sports Illustrated – blanketed the slopes of his most popular runs in shredded ice.[8] The February edition of Eastern Skier reported that over the New Year’s Eve holiday, Schoenknecht rented a woodchipper and bought 450 tons of ice. Pulverized ice was not new to skiing. It had been used “occasionally and expensively to repair damage to important racing and slalom runs.” But covering an entire run was unconventional (as was Schoenknecht himself, by all accounts).

The process was onerous, taking 52 hours to crush and spread enough ice to cover 1,600 feet of slope. Reflecting the comic aspects of the situation, Eastern Skier published a strange photograph on their front page. A blurry black box, with a snake-like hose attached to the left side, sat on the edge of the ski run. In the foreground, blocks of ice were piled haphazardly. Unfortunately for the skiers, it seemed that people had to ski under the cloud of ice that emerged from the Martian-like machine. To the modern eye (and likely to the eyes of skiers then), the skiing looked awful.

Nevertheless, the “Snow Man” proved the old saying that “every ski day is a good ski day.” Eastern Skier reported that “eager skiers ground up the chunks in a pulverizing machine and sprayed the heavy, corn-snow-like stuff over 150,000 sq. feet of slope.” At the end of the weekend, Schoenknecht impressively broke even. That said, the process was expensive and relied on more ice than was readily available. Luckily, three airplane engineers turned ski manufacturers, who lived and worked only a few towns away, were seeking a better solution.

During World War II, Art Hunt, Wayne Pierce, and Dave Richey had worked on projects to prevent ice buildup on airplane wings. Following the war, they decided to leave airplane wings behind in favor of the burgeoning winter outdoor gear industry. Tey Manufacturers (a combination of the last letters of their last names) was also going through a rough patch in 1949. If people could not ski without snow, manufacturers could not sell skis. During the war, Pierce had read a report from a Canadian engineer who had used a fan to blow water at a plane to simulate icy conditions for research purposes. Instead of freezing to the wings, it sprayed little particles of ice. Pierce saw an opportunity.

The first snowmaker was an unimpressive invention. In reality, it was little more than pressurized water being sprayed out of very small holes. That said, the machine was imaginative. Both Schoenknecht and the Toronto Ski Club conceptualized snow as a thing on the ground. Their innovation revolved around finding a substance (ice) that could be taken from a larger solid form and then ground, chipped, or shaved to produce something closer to snow. But Tey Manufacturers made a cognitive leap. They thought about the way water interacted with the atmosphere to create natural snow. In other words, they devised a way to replace natural snow by modifying weather (in miniature).

The key aspect of this interaction was not simply liquid water but cold air. When the water and the cold air collided, the air absorbed the heat from the water, and it rapidly turned into tiny particles of ice. If the air was cold enough, a ski center could now make snow. The economic key to the process was cold air, which was much easier to come by in the Appalachian Mountains than natural snowfall.

While Tey took out a patent, ski hill owners jerry-rigged their own versions. Increasingly, these machines relied on a combination of pressurized air and pressurized water. In effect, the air bashed into the water, breaking it apart into the tiniest particles possible, making the water freeze faster when it came out of the snow machine. The first machines were tested at Big Boulder in Pennsylvania and at Schoenknecht’s Mohawk Mountain. By 1960, the machines were spreading rapidly, with at least twenty resorts using them in the east.

What separated these machines from earlier attempts to mimic snowpack was the idea that they were making actual snow – although there were and continue to be debates about that – not just processing ice into something snow-like. For instance, in 1950, in the New York Times’ first review of the snow, the reporter commented that the machines created “hexagonal snow crystals with the same qualities as natural snow.”[9] (For what it is worth, the reporter was wrong about the shape of the crystals.) Seven years later, William Walsh, who worked for Larchmont Irrigation, the premier snowmaking company at the time, was more discerning. In an article in Eastern Ski Annual, he noted that artificial snow “differs from most natural snow in its initial texture.” But, he also asserted (in a subtitle), that “Man-Made Snow Is Real Snow.”[10] Walsh reflected that it was the cold that mattered. He wrote that artificial snow depended “upon the weather conditions.” He continued to argue that weather had to be cold enough to have previously frozen the ground, and ambient temperatures had to be below 32 degrees Fahrenheit (0 degrees Celsius). In many ways, Walsh’s enthusiasm was prescient. By 1983, even Alta, one of the snowiest resorts in the United States, embraced the value of the cold by installing a snowmaking system.

Conclusion

Snowmaking fundamentally changed the ski industry. In effect, by guaranteeing snow in some places, it became imperative for other ski resorts to do the same. In certain respects, A.W. Coleman was correct when they wrote that snow was “white gold.” At the same time, snowmaking technology dramatically changed the ski industry’s relationship to natural systems. Rather than sitting passively, and waiting for the next snowfall, resorts around the country now see snow as something they can produce by working with cold weather. Because of this technology, skiing is now possible anywhere that temperatures regularly drop below freezing. At the same time, snowmaking is economically necessary (even in the snowy mountains of the American West) because skiers have come to expect snow-covered mountains from Thanksgiving to Easter.

It was certainly irresponsible (if not unethical) for ski resorts like Loveland, Copper, and Arapaho Basin to blow snow while forest fires still burned in Colorado. That said, while snowmaking may be harmful to the environment, snowmaking technology provided these Colorado ski resorts with a different relationship to weather than ski centers had in the 1940s. Snow guns used the freezing temperatures as part of their technological apparatus, building a different economic relationship between ski resorts, snow, skiers, and weather.

The history of snowmaking provides a different perspective on the relationship between winter weather, technology, and skiing. Where before ski centers in the Northeast and mid-Atlantic relied on always inconsistent snowfall (which was not a result of climate change) they came to depend on consistently cold weather in order to manufacture snow. In a sense, the ski industry, through snowmaking, has made cold as productive as natural snow. And they have profited greatly from this change. In the now 70 years since the snow machine’s invention, approximately 90% of ski resorts in the United States use snowmaking. And with this technology, skiing has grown into a $20 billion industry, employing more people than extractive industries.

Snowmaking is not necessarily sustainable. But looking at its history calls into question Wired’s claim that snow guns are used to “fight climate change.” Snowmaking was developed before climate change was on the political radar. But, the great irony of snowmaking is that despite discourses that it can save the ski industry from climate change, snowmaking technology needs the cold. In other words, it is as dependent on climate and weather as real snow.

Jesse Ritner is a Ph.D. candidate in history at the University of Texas, Austin, specializing in environmental history. His dissertation is tentatively titled “Making Snow: Weather, Technology, and the Rise of the U.S. Ski Industry, 1900-present.” Along with studying history, Jesse is also a passionate skier who grew up skiing on artificial snow.

Suggested Readings:

- Annie Gilbert Coleman, Ski Style: Sport and Culture in the Rockies (University Press of Kansas, 2004).

- Gregory Zielinski and Barry Keim, New England Weather, New England Climate (University of New Hampshire, 2003).

- Hal Clifford, Downhill Slide: Why the Corporate Ski Industry Is Bad for Skiing, Ski Towns, and the Environment, 1st Edition (San Francisco: Sierra Club Books, 2003).

- Jim Steenburgh, Secrets of the Greatest Snow on Earth: Weather, Climate Change, and Finding Deep Powder in Utah’s Wasatch Mountains and around the World, 1st Edition (Utah State University Press, 2014).

- John Fry, The Story of Modern Skiing (University Press of New England, 2006).

- Mergen Bernard, Snow in America (Washington, D.C: Smithsonian, 1997).

Copyright 2020 Jesse Ritner

Notes

[1] A.W. Coleman, “White Gold,” Vermont Life, 1946, 5.

[2] Charles R. Goeldner and Stacy Standley, “Skiing Trends,” https://www.nrs.fs.fed.us/pubs/gtr/gtr_ne57/gtr_ne57_1_105.pdf (accessed November 2, 2020).

[3] “Number of ski resorts operating in the U.S. from 1990/91 to 2019/20,” Statista, https://www.statista.com/statistics/206534/number-of-ski-resorts-operating-in-the-us-since-1990/#:~:text=This%20statistic%20depicts%20the%20number,operation%20in%20the%20United%20States. (accessed November 2, 2020).

[4] Eric Niiler, “Ski Resorts Fight Climate Change With Snow Guns and Busses,” Wired: (March 26, 2018).

[5] “Walt Sprays 450 tons of Ice Over Bare Mohawk Slope, Breaks Even,” Eastern Skier (February 1, 1950), 1.

[6] Fred A. Hall, “Manufacturing Snow by Shaving,” Canadian Ski Year Book (1934), 51.

[7] https://en.wikipedia.org/wiki/Ski_skins

[8] Huston Horn, “Vermont’s Phenomenal Snow Man,” Sports Illustrated (March 20, 1961) https://vault.si.com/vault/1961/03/20/vermonts-phenomenal-snow-man (accessed October 10, 2020).

[9] “Two Processes are Developed for Making Snow for Skiers,” New York Times, December 31, 1950, 15.

[10] Italics in the original.